HDPE Reducer

Features

• Material: PE100

• Outstanding flexibility.

• Safe and easy attachment by butt welding.

• High impact resistance even at very low temperatures

DOWNLOAD SPECIFICATIONS (PDF)

HDPE Tees

Features

• Material: PE100

• Outstanding flexibility.

• Safe and easy attachment by butt

welding.

• High impact resistance even at

very low temperatures

DOWNLOAD SPECIFICATIONS (PDF)

HDPE Tees reduced

Features

• Material: PE100

• Outstanding flexibility.

• Safe and easy attachment by butt welding.

• High impact resistance even at very low temperatures

DOWNLOAD SPECIFICATIONS (PDF)

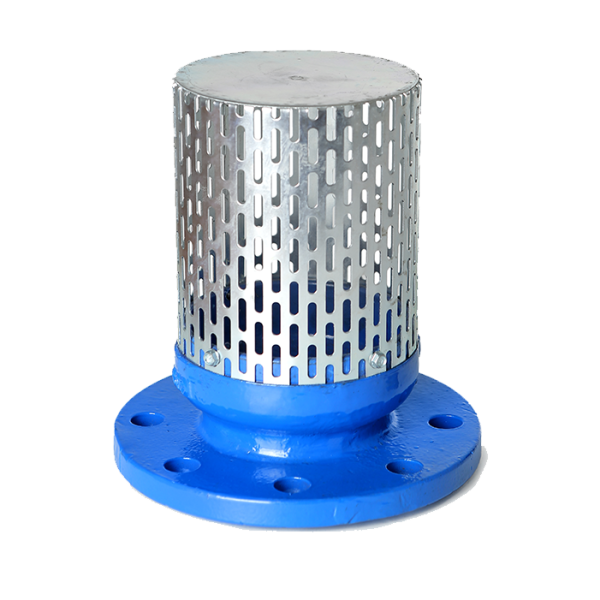

Inlet strainer without valve

Features

• Body Ductile iron or steel

body.

• Working Pressure: PN10,

PN16.

• Available range: DN 50-500.

• Epoxy coated from the inside

and outside, min 250 μm

• Product color: Blue RAL

5005

DOWNLOAD SPECIFICATIONS (PDF)

Loose steel flange for HDPE

Features

• For polyethylene stub

ends.

• Material: Steel S235JR.

• Working Pressure: PN10,

PN16, PN25 and PN40.

• Protection: zinc plated,

epoxy coated or

thermoplastic.

• Dimensions in accordance

with EN 1092-1+A1:2013/

AC:201

DOWNLOAD SPECIFICATIONS (PDF)

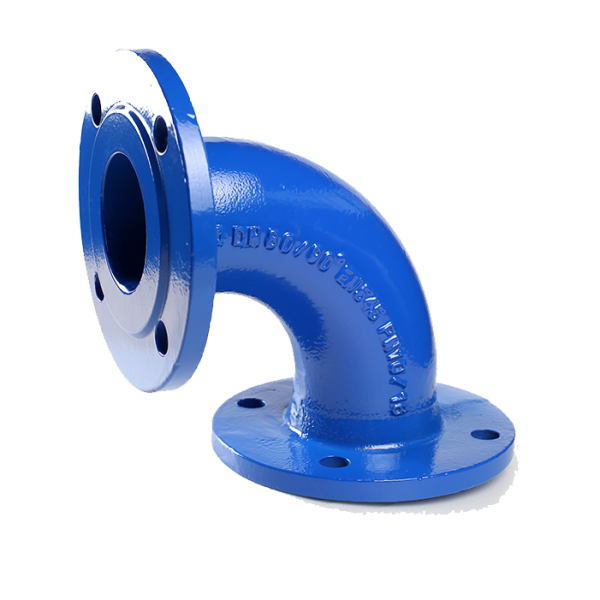

Manhole cover – type medium

Features

Material: EN124, Ductile iron GJS,

bitumen coated

Capacity: Class B125(150), in

accordance with EN 124

Purpose: To close the sewage shafts,

etc.

Usage: On sidewalks, pedestrian

walks, bicycle paths or parking for light

vehicles

Versions: Fixed

DOWNLOAD SPECIFICATIONS (PDF)

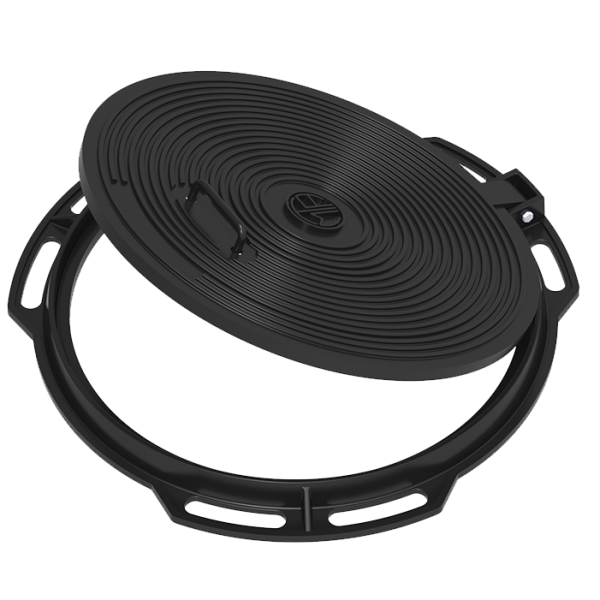

Manhole cover for watermeter

Features

Material: Ductile iron GJS, bitumen coated

Capacity: Class A15, in accordance with

EN 124

Purpose: Closure of shafts for water

meters or house connections with

waterline

Usage: On sidewalks, pedestrian walks,

bicycle paths and parks

Versions: Fixed

DOWNLOAD SPECIFICATIONS (PDF)

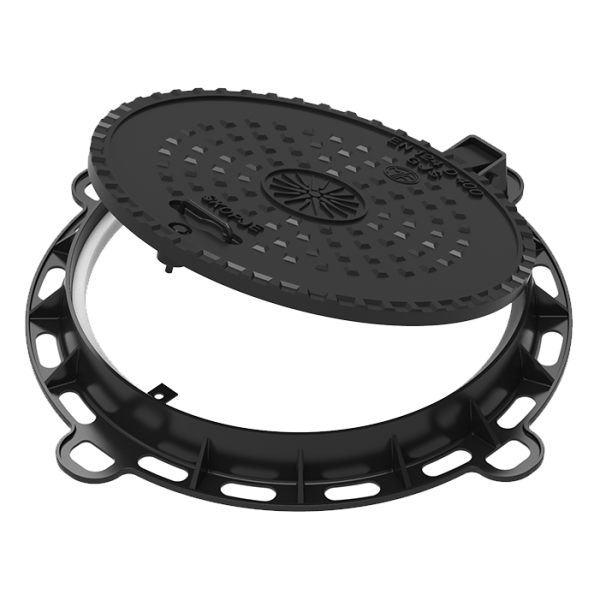

Manhole cover without openings

Features

Material: Ductile iron GJS, bitumen coated

Capacity: Class C250 и D 400, in accordance with EN 124

Purpose: To close sewage shafts, with intensive and regular

access, frequent openings

Usage: For streets with high traffic intensity of regular and

heavy vehicles, with normal speed

Versions: Fixed with openings and without openings. With/

without automatic closin

DOWNLOAD SPECIFICATIONS (PDF)

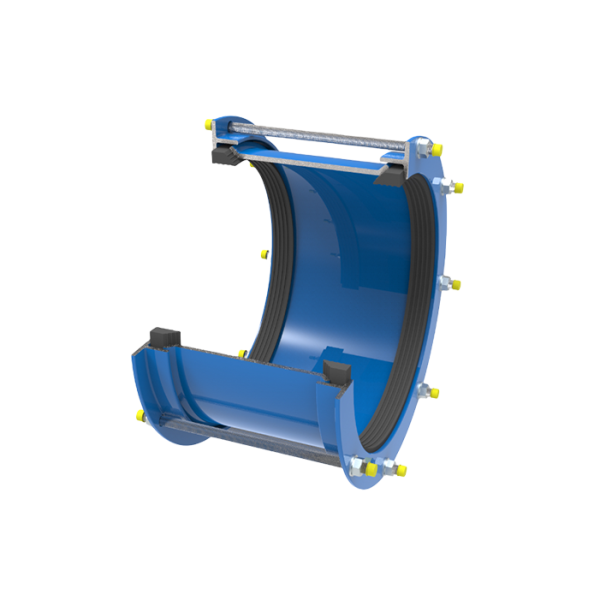

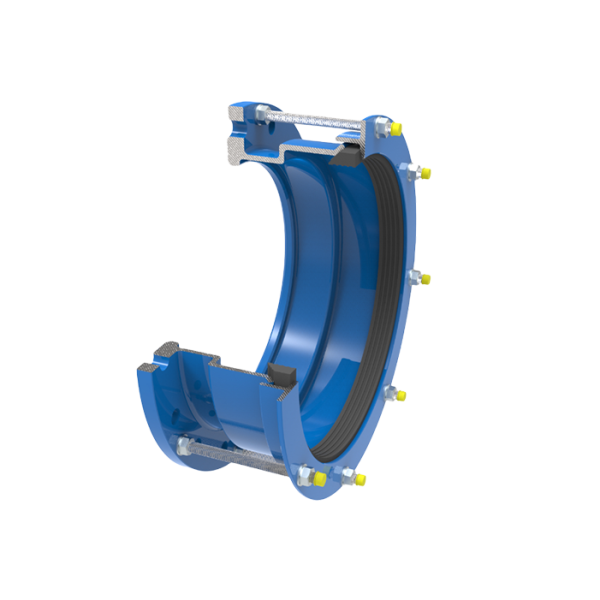

Max coupling

Features:

• Body and end ring made of ductile iron

material EN-GJS-500 (GGG 50) in

accordance with EN 1563:2018 standard

(optional body and end caps from hot

rolled structural steel)

• Couplings produced in accordance with

EN 14525:2004

• Protection with epoxy coating or black

thermoplastic coating confirmed by a

health inspection certificate

• PN16 working pressure.

• Equipped with steel zinc coated bolts,

nuts and washers

• EPDM rubber seals in accordance with EN

681- 1:1996

• High Tolerance mechanical pipe fittings.

• Angular deflection +/- 6

DOWNLOAD SPECIFICATIONS (PDF)

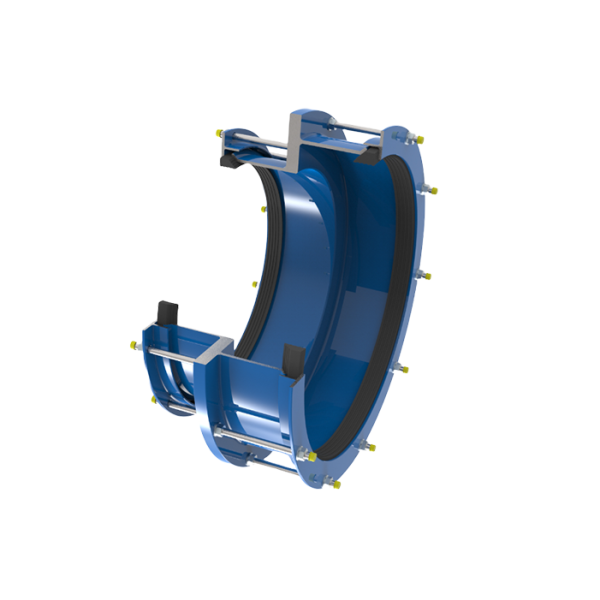

Max Flange adaptor

Features:

• Body and end rings are made оf ductile

iron material EN-GJS-500 (GGG 50) in

accordance with EN 1563:2018 standard

(optional body and end cap from hot

rolled structural steel)

• Flange Adaptors are produced in

accordance with EN 14525:2004

• Surface protection by epoxy coating or

black thermoplastic coating confirmed

by health inspection certificate

• PN10, PN16 working pressure.

• Flanges in accordance with EN1092-

2:1997

• Equipped with steel zinc plated bolts,

nuts and washers

• EPDM rubber seals in accordance with

EN 681-1:1996

• High Tolerance mechanical pipe fittings.

• Angular deflection +/- 4⁰

DOWNLOAD SPECIFICATIONS (PDF)

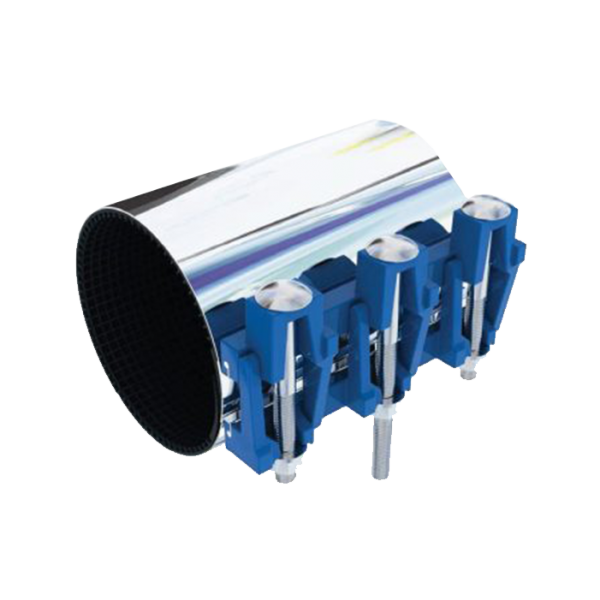

Repair clamp Type DI

Product characteristics

Repair clamps are flexible clamps composed of one, two or three stainless steel parts with ductile iron clamps attached to their ends with bolts and nuts for tightening. They are intended for easy, fast and permanent repair of corroded or damaged water pipes. The central bolt is with extended length for easier installation in difficult conditions. Working pressure PN10/16.Material

- Body and side plates made of stainless steel 1.4301 (AISI 304)

- Clamps of ductile iron in accordance with EN 1563:2018

- Surface protection of clamps with epoxy paint or black thermoplastic confirmed by an accredited laboratory issued health safety report

- EPDM rubber seal in accordance with the EN 681 -1:1996/A1:1998 with an accredited laboratory issued health safety certificate

- Screws, nuts and washers – Stainless steel (Class A21A4)

Field of application

- Above the ground installation.

- Underground installation.

Repair clamp Type S

Product characteristics

Repair clamps are flexible clamps made of one or two stainless steel parts wrapped with rubber gasket. They are intended for easy, fast and permanent repair of corroded or damaged water pipes.

The single band repair clamps are with tolerance of 10mm,

whereas the double band repair clams have 20mm tolerance.

Material

• Body and bands – stainless steel

• Rubber gasket – EPDM or NBR

• Nuts, bolts and washers – stainless steel

Field of application

• Above ground installation.

• Underground installation

DOWNLOAD SPECIFICATIONS (PDF)

Resilient Seated Gate Valve – F5

Features:

• Replaceable O-rings

• Low torque operation

• Rubber encapsulated wedge (optional

wedge with integrated sliders).

• Clockwise closing direction

• Epoxy coating protection in

accordance with EN 14901:2014

confirmed by health inspection

certificate

• Product color: Blue RAL 5005

• Maximum temperature: 80°C

DOWNLOAD SPECIFICATIONS (PDF)

Resilient seated gate valve F4

Features

- Replaceable O-rings

- Rubber encapsulated wedge (optional wedge with integrated sliders)

- Clockwise closing direction

- Epoxy coating protection in accordance with EN 14901:2014 confirmed by health inspection certificate

- Product color: Blue RAL 5005

- Maximum temperature: 80°C

Rubber Expansion Joint

• Flexible main shell made of EPDM in accordance

with EN 681-1:1996/A3:2005 with inner

reinforcements to provide consistency

• Steel galvanized loose flanges in accordance with

EN 1092-1:2007+A1:2013/AC:2014

• Working Pressure: PN10, PN16.

• Working Pressure: PN10, PN16.

• Available range: DN 50-600.

• Easy to install due to their light weight and

relatively small space requirement.

• Noise and vibrations caused by equipment such as

pumps are absorbed by Rubber Joints.

• Rubber Joints balance thermal movements appear

in any rigid system due to temperature changes.

Single chamber air valve

Features

• Design: EN 1074-4:2000

• Available range of DN sizes DN 50 to DN 100.

• Epoxy coated from the inside and outside, min 250

μm in accordance with EN 14901:2014

• Product color: Blue RAL 5005.

• Working pressure PN10 and PN16

DOWNLOAD SPECIFICATIONS (PDF)

Sluice gates Penstocks

Features

• Purpose: Wastewater treatment and mini hydro power plants.

• Made in accordance with EN 1085:2007

• Three or four side sealing

• Manual board lifting (option with hydraulic drive)

• Material:

Frame: Stainless steel in accordance with EN1.4301/X5CrNi 18-10 AISI 304

• Table: Hot rolled structural steel in accordance with EN 10025-2:2004 (option

stainless steel in accordance with EN1.4301/X5CrNi 18-10 AISI 304)

Stem: Stainless steel in accordance with EN 1.4301/X5CrNi 18-10 AISI 304 or

hydraulic cylinder with clip material C45E (1.991) in accordance with EN10277-

5:2008

Sealing tape: Hot roller structural in accordance with EN 10025-2:2004 or

stainless steel in accordance with EN 1.4301/X5CrNi 18-10 AISI 304

• Seal: EPDM rubber in accordance with EN 681-1:1996/AC:2002

• Surface protection by materials made of hot rolled structural steel with epoxy or

polyurethane color

DOWNLOAD SPECIFICATIONS (PDF)

Steel Max coupling for large diameters

Features:

• Body and end ring made of hot rolled

products of structural steel St235JR in

accordance with EN 10025-2:2019 or ductile

iron in accordance with EN 1563:2018

• Couplings produced in accordance with EN

14525:2004

• Protection with epoxy coating in accordance

with EN 14901:2014 or black thermoplastic

coating confirmed by health inspection

certificate

• PN16 working pressure

• Equipped with steel zinc coated bolts, nuts

and washers

• EPDM rubber seal in accordance with EN

681- 1:1996

• High tolerance mechanical pipe fitings

DOWNLOAD SPECIFICATIONS (PDF)

Steel max flange adapter for large diameters

Features:

• Body and end ring made of hot rolled products of structural

steel ST235JR in accordance with EN 10025-2:2019 оr ductile

iron in accordance with EN 1563:2018

• Flange Adaptors produced in accordance with EN 14525:2004

• Epoxy coating protection in accordance with EN 14901:2014 or

black thermoplastic coating confirmed by health inspection

certificate

• PN10, PN16 working pressure

• Connecting dimensions in accordance with EN 1092-

1:2007+a1:2013/AC:2014 or EN 1092-2:1997

• Equipped with steel zinc coated bolts, nuts and washers

• EPDM rubber seal in accordance with EN 681-1:1996

• High tolerance mechanical pipe fitting

DOWNLOAD SPECIFICATIONS (PDF)

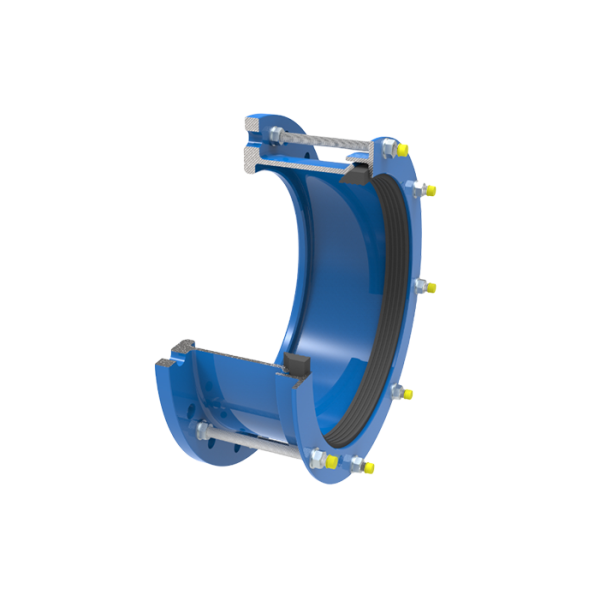

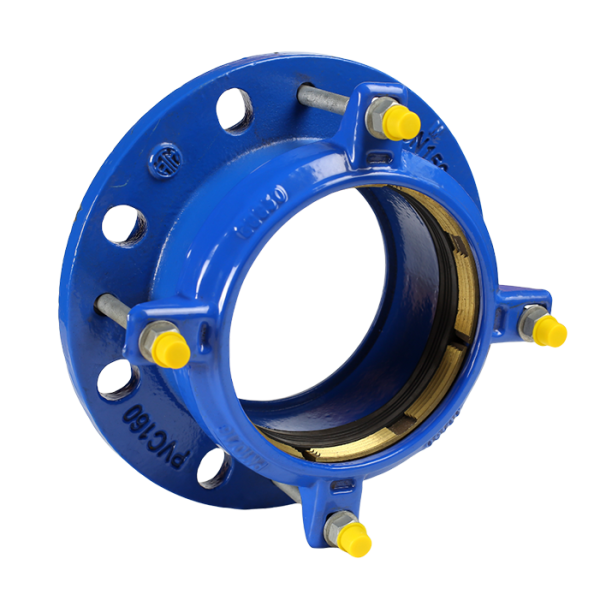

Strained Flange Adapter for HDPE and PVC pipe

Features:

• Body and end rings are made of

ductile iron material EN- GJS-500

(GGG 50) in accordance with EN

1563:2018 standard

• Flange Adaptоrs produced in

accordance with EN 14525:2004

• Epoxy coating protection in

accordance with EN14901:2014 or

black color thermoplastic coating

confirmed by health inspection

certificate

• PN10, PN16 working pressure.

• Flanges in accordance with

EN1092- 2:1997

• Equipped with steel zinc plated

bolts, nuts and washers

• EPDM rubber seals in accordance

with EN 681-1:1996

• Angular deflection +/- 3.5⁰

DOWNLOAD SPECIFICATIONS (PDF)