Swing check valve

Features

• Rubber encapsulated disc.

• Suitable for both horizontal and vertical

installation.

• Working Pressure: PN10, PN16.

• Available range: DN 50-300.

• Epoxy coated from the inside and outside,

min 250 μm in accordance with

EN 14901:2014

• Product color: Blue RAL 5005.

DOWNLOAD SPECIFICATIONS (PDF)

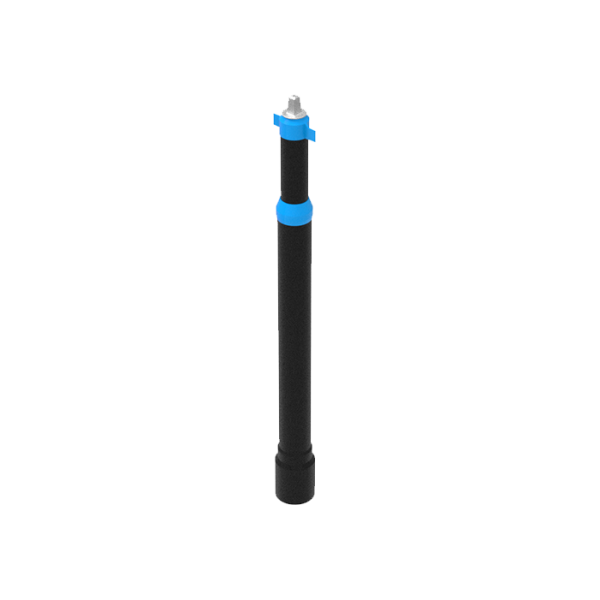

Telescopic service spindle

Features

• Allows valve opening and closing

• Easy to install without special tools

• Protection against dirt

• Adjustable in any position within the

range, and self-holding

• The protective tube, cap and clutch

between the telescopic parts are

integrated in a stable assembly

• With ranges from 0,7 to 2,5 m

DOWNLOAD SPECIFICATIONS (PDF)

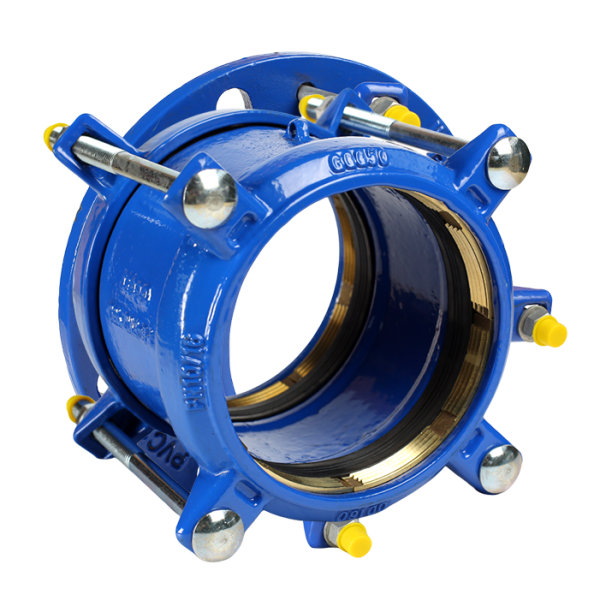

Tensile Restrained Coupling for HDPE and PVC pipe

Features:

• Body and end ring are made of ductile iron material EN-GJS-500 (GGG

• 50) in accordance with EN 1563:2018

• Couplings for PE and PVC produced in accordance with EN 14525:2004

• Protection by epoxy coating or thermoplastic coating in accordance with

EN 14901:2014 or black color confirmed by health inspection certificate

• PN16 working pressure.

• Equipped with steel zinc plated bolts, nuts and washers

• EPDM rubber seals in accordance with EN 681-1:1996

• High Tolerance mechanical pipe fittings

• Angular deflection +/- 4⁰

DOWNLOAD SPECIFICATIONS (PDF)

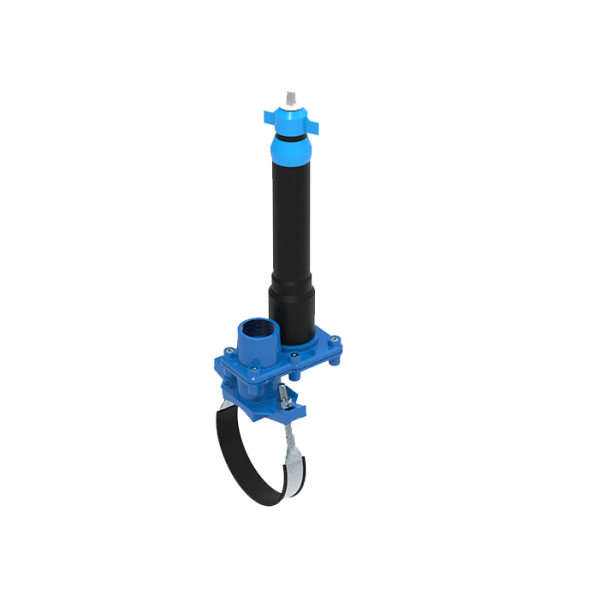

Two part tapping saddle for PE-PVC pipes for tapping at full operating pressure

Features

• For installation on PE and PVC pipes

• For horizontal or vertical installation

• Operating pressure PN16 bar, hydraulically tested in accordance with EN12266-1: 2012

• Body made of ductile iron EN-GJS-500-7 in accordance with EN 1563:2018

• Epoxy paint surface protection of min 250μm in accordance with EN 14901:2014 or

thermoplastic confirmed by an accredited laboratory issued health inspection certificate

EPDM rubber seals in accordance with EN 681-1:1996/A3:2005 confirmed with an

accredited laboratory issued health inspection certificate

• Connector with internal female thread G1”, G1½” and G2” in accordance with EN 10226-

1:2004

• Additional material coupled with connection to PE hose min. Ø32 made of brass. The thread

of the additional material is in accordance with the ICC EN 10226-1:2004 and is designed

for a working pressure of 16 bar

• Telescopic extension spindle with ranges from 0,7 m to 2,5 m made of PVC and galvanized

steel with epoxy protected or galvanized coupling elements

DOWNLOAD SPECIFICATIONS (PDF)

Underground Hydrant DN80

Features:

• Design in accordance with EN 1074-6:2008:,

• Body, claw, cap and cone made of ductile ironENGJS-400-15 (GGG40) or EN-GJS-500-7 (GGG50)in

accordance with EN 1563:2011.

• Flange dimensions in accordance with EN 1092-

2:1997

• Hydraulically tested in accordance with EN 12266-

1:2012 with an accredited laboratory issued report.

• Automatic outlet for faster water draining

• Stainless steel spindle fixed with brass nut and

o-rings

• All elastomeric seals for underground hydrants

that come in contact with water are made of EPDM

material (antibacterial rubber) in accordance

with EN 681-1:1996/A3:2005 with an accredited

laboratory issued hygiene certificate.

• Surface corrosion protection with externally and

internally applied epoxy coating with minimal

thickness of 250μm in accordance with

EN 14901:2014

Underground Hydrant DN80 Type “ATA-T2”

Features:

• Design in accordance with EN 1074- 6:2008:,

• Body, claw, cap and cone made of ductile iron

EN-GJS-400-15 (GGG40) or EN-GJS-500-7

(GGG50) in accordance with EN 1563:2011.

• Flange dimensions in accordance with EN

1092-2:1997

• Hydraulically tested in accordance with EN

12266-1:2012 with an accredited laboratory

issued report.

• With ball safety system for automatic closing

and single or double automatic outlet for

faster water draining

• Stainless steel spindle fixed with brass nut

and o-rings

• All elastomeric seals for underground

hydrants that come in contact with water are

made of EPDM material (antibacterial rubber)

in accordance with EN 681-1:1996/A3:2005

with an accredited laboratory issued hygiene

certificate.

• Surface corrosion protection with externally

and internally applied epoxy coating with

minimal thickness of 250μm in accordance

with EN 14901:2014DOWNLOAD SPECIFICATIONS (PDF)

Universal tapping bridge for tapping at full operating pressure

Features

• For installation on cast-iron, ductile, steel and asbestos cement pipes

• For horizontal or vertical installation

• Operating pressure PN16 bar, hydraulically tested in accordance with EN12266-1: 2012

• Body made of ductile iron EN-GJS-500-7 in accordance with EN 1563:2018

• Epoxy paint surface protection of min 250μm in accordance with EN 14901:2014 or

thermoplastic confirmed with an accredited laboratory issued health inspection certificate

• EPDM rubber seals in accordance with EN 681-1:1996/A3:2005 confirmed with an accredited

laboratory issued health inspection certificate

• Connector with internal female thread G1”, G1½” and G2” in accordance with EN 10226-

1:2004

• Additional material coupled with connection to PE hose min. Ø32 made of brass. The thread

of the additional material is in accordance with the ICC EN 10226-1:2004 and is designed for

working pressure of 16 bar

• Telescopic extension spindle with ranges from 0,7 m to 2,5 m made of PVC and galvanized

steel with epoxy protected coupling elements

• Belt, rods, washers and nuts made of X5CrNi18-10

DOWNLOAD SPECIFICATIONS (PDF)

Wall sleeve flange Split puddle flange

Features

• Made from constructive steel min. St235JR

• For welding or installation on pipes that pass through

concrete walls

• Strengthens and fixes the pipe

• Per request, wall flanges can be made up to DN1600

DOWNLOAD SPECIFICATIONS (PDF)

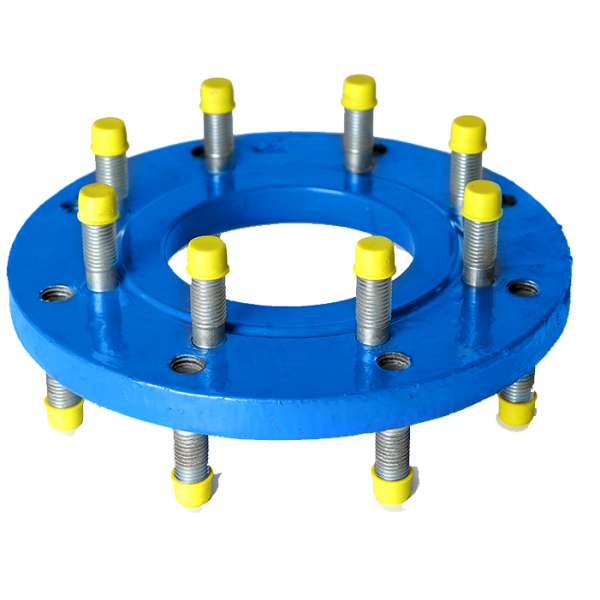

XR – Tapers flange

Features:

• The pressure reducing flange allows for substantial reduction of the nominal

diameter and is very practical because of its overall short length

• Dimensions in accordance with EN 1092-1:2007+A1:2013/AC:2014

• Material: steel S235JR

• Zinc plated bolts in accordance to DIN975

• Working pressure: PN10 and PN16.

• Epoxy paint surface protection of min 250μm or thermoplastic confirmed by an

accredited laboratory issued health inspection certificate

DOWNLOAD SPECIFICATIONS (PDF)