Related products

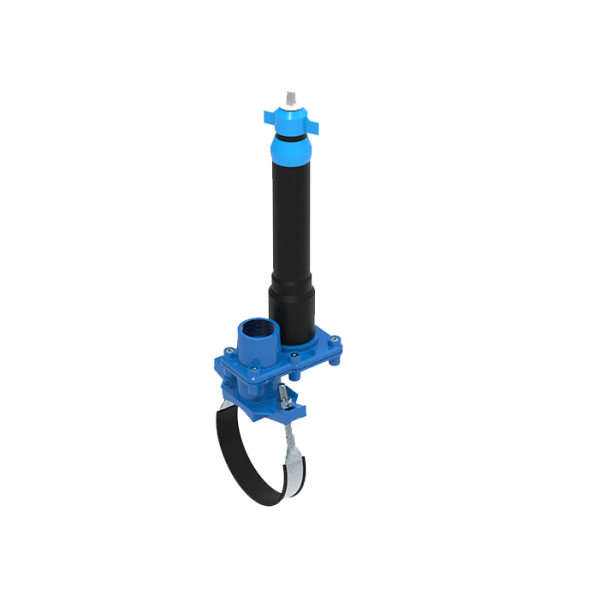

Universal tapping bridge for tapping at full operating pressure

Features

• For installation on cast-iron, ductile, steel and asbestos cement pipes

• For horizontal or vertical installation

• Operating pressure PN16 bar, hydraulically tested in accordance with EN12266-1: 2012

• Body made of ductile iron EN-GJS-500-7 in accordance with EN 1563:2018

• Epoxy paint surface protection of min 250μm in accordance with EN 14901:2014 or

thermoplastic confirmed with an accredited laboratory issued health inspection certificate

• EPDM rubber seals in accordance with EN 681-1:1996/A3:2005 confirmed with an accredited

laboratory issued health inspection certificate

• Connector with internal female thread G1”, G1½” and G2” in accordance with EN 10226-

1:2004

• Additional material coupled with connection to PE hose min. Ø32 made of brass. The thread

of the additional material is in accordance with the ICC EN 10226-1:2004 and is designed for

working pressure of 16 bar

• Telescopic extension spindle with ranges from 0,7 m to 2,5 m made of PVC and galvanized

steel with epoxy protected coupling elements

• Belt, rods, washers and nuts made of X5CrNi18-10

DOWNLOAD SPECIFICATIONS (PDF)

Two part tapping saddle for PE-PVC pipes for tapping at full operating pressure

Features

• For installation on PE and PVC pipes

• For horizontal or vertical installation

• Operating pressure PN16 bar, hydraulically tested in accordance with EN12266-1: 2012

• Body made of ductile iron EN-GJS-500-7 in accordance with EN 1563:2018

• Epoxy paint surface protection of min 250μm in accordance with EN 14901:2014 or

thermoplastic confirmed by an accredited laboratory issued health inspection certificate

EPDM rubber seals in accordance with EN 681-1:1996/A3:2005 confirmed with an

accredited laboratory issued health inspection certificate

• Connector with internal female thread G1”, G1½” and G2” in accordance with EN 10226-

1:2004

• Additional material coupled with connection to PE hose min. Ø32 made of brass. The thread

of the additional material is in accordance with the ICC EN 10226-1:2004 and is designed

for a working pressure of 16 bar

• Telescopic extension spindle with ranges from 0,7 m to 2,5 m made of PVC and galvanized

steel with epoxy protected or galvanized coupling elements

DOWNLOAD SPECIFICATIONS (PDF)

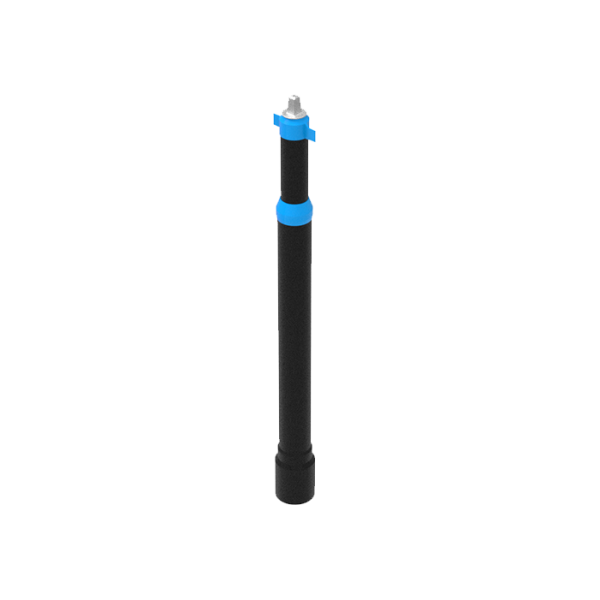

Telescopic service spindle

Features

• Allows valve opening and closing

• Easy to install without special tools

• Protection against dirt

• Adjustable in any position within the

range, and self-holding

• The protective tube, cap and clutch

between the telescopic parts are

integrated in a stable assembly

• With ranges from 0,7 to 2,5 m

DOWNLOAD SPECIFICATIONS (PDF)