Steel max flange adapter for large diameters

Features:

• Body and end ring made of hot rolled products of structural

steel ST235JR in accordance with EN 10025-2:2019 оr ductile

iron in accordance with EN 1563:2018

• Flange Adaptors produced in accordance with EN 14525:2004

• Epoxy coating protection in accordance with EN 14901:2014 or

black thermoplastic coating confirmed by health inspection

certificate

• PN10, PN16 working pressure

• Connecting dimensions in accordance with EN 1092-

1:2007+a1:2013/AC:2014 or EN 1092-2:1997

• Equipped with steel zinc coated bolts, nuts and washers

• EPDM rubber seal in accordance with EN 681-1:1996

• High tolerance mechanical pipe fitting

Related products

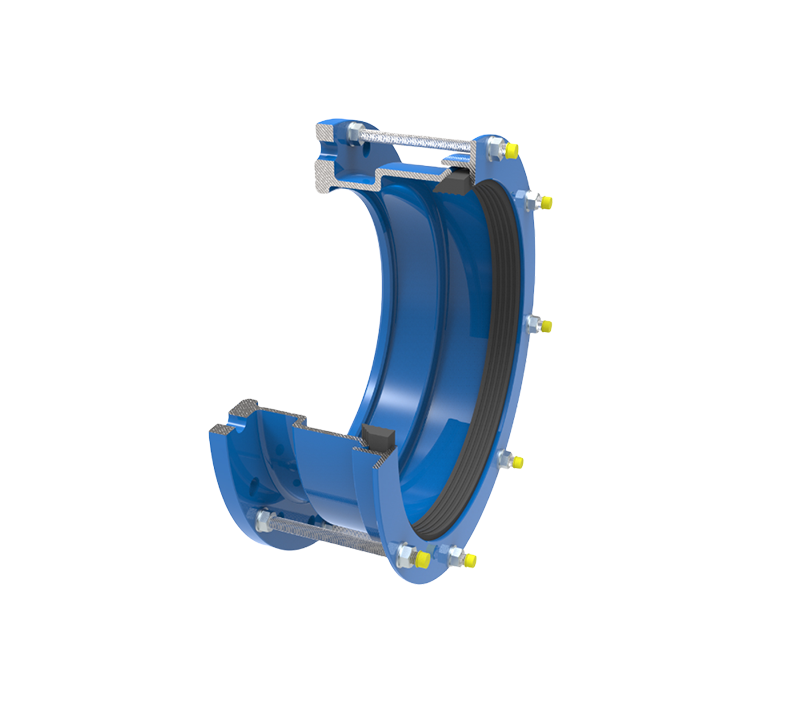

Max Flange adaptor

Features:

• Body and end rings are made оf ductile

iron material EN-GJS-500 (GGG 50) in

accordance with EN 1563:2018 standard

(optional body and end cap from hot

rolled structural steel)

• Flange Adaptors are produced in

accordance with EN 14525:2004

• Surface protection by epoxy coating or

black thermoplastic coating confirmed

by health inspection certificate

• PN10, PN16 working pressure.

• Flanges in accordance with EN1092-

2:1997

• Equipped with steel zinc plated bolts,

nuts and washers

• EPDM rubber seals in accordance with

EN 681-1:1996

• High Tolerance mechanical pipe fittings.

• Angular deflection +/- 4⁰

DOWNLOAD SPECIFICATIONS (PDF)

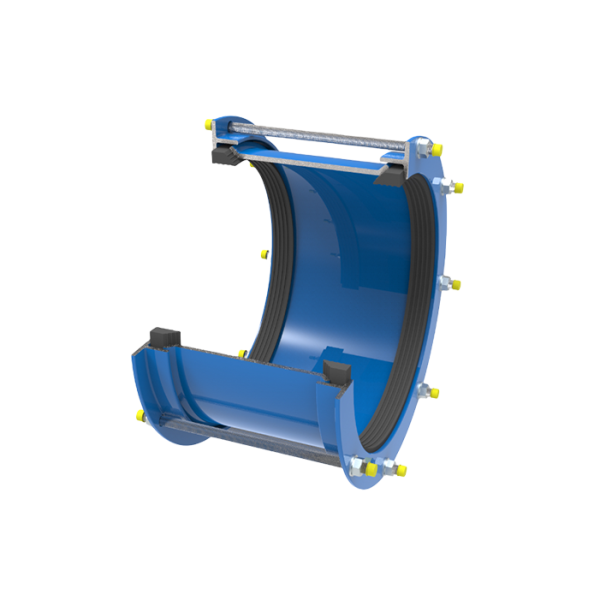

Tensile Restrained Coupling for HDPE and PVC pipe

Features:

• Body and end ring are made of ductile iron material EN-GJS-500 (GGG

• 50) in accordance with EN 1563:2018

• Couplings for PE and PVC produced in accordance with EN 14525:2004

• Protection by epoxy coating or thermoplastic coating in accordance with

EN 14901:2014 or black color confirmed by health inspection certificate

• PN16 working pressure.

• Equipped with steel zinc plated bolts, nuts and washers

• EPDM rubber seals in accordance with EN 681-1:1996

• High Tolerance mechanical pipe fittings

• Angular deflection +/- 4⁰

DOWNLOAD SPECIFICATIONS (PDF)

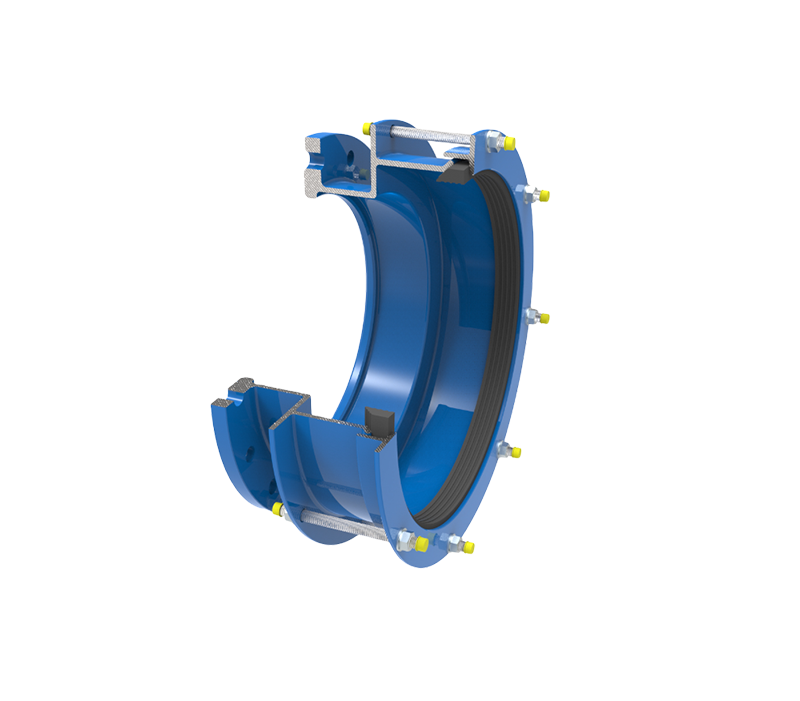

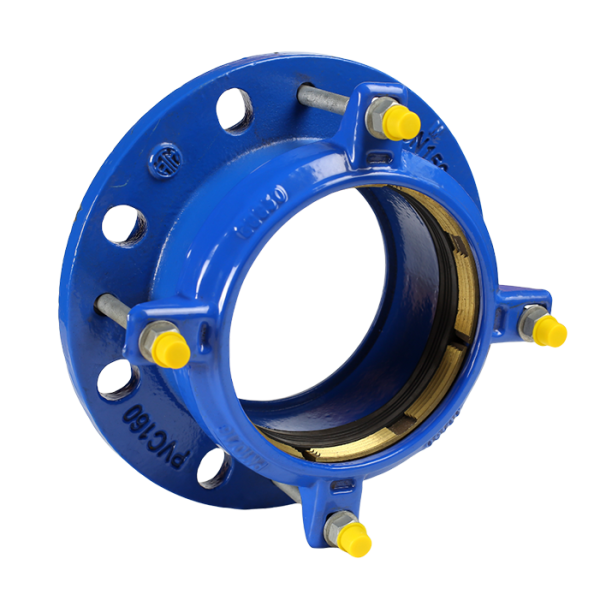

Strained Flange Adapter for HDPE and PVC pipe

Features:

• Body and end rings are made of

ductile iron material EN- GJS-500

(GGG 50) in accordance with EN

1563:2018 standard

• Flange Adaptоrs produced in

accordance with EN 14525:2004

• Epoxy coating protection in

accordance with EN14901:2014 or

black color thermoplastic coating

confirmed by health inspection

certificate

• PN10, PN16 working pressure.

• Flanges in accordance with

EN1092- 2:1997

• Equipped with steel zinc plated

bolts, nuts and washers

• EPDM rubber seals in accordance

with EN 681-1:1996

• Angular deflection +/- 3.5⁰

DOWNLOAD SPECIFICATIONS (PDF)

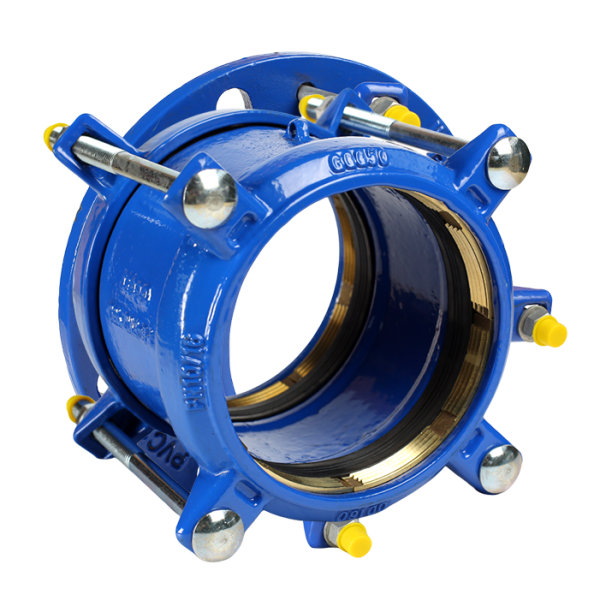

Coupling with restrains against pull-out

Code No. АТА 07264

Features

- For installation on cast iron / ductile, steel, Asbestos-cement, PE and PVC pipes

- Produced in accordance with EN 14525: 2004

- The body, closing ring and clamps made of hot rolled structural steel in accordance with EN 10025- 2:2019 or ductile iron in accordance with EN 1563:2018

- Epoxy paint surface protection of min 250 μm in accordance with EN 14901:2014 or black thermoplastic confirmed by an accredited laboratory issued health safety report

- Operating pressure PN10, PN16, PN25

- Galvanized steel or cast-iron pull-out clamps

- EPDM rubber seal in accordance with the EN 681-1:1996 with an accredited laboratory issued health safety certificate

- Angle deviation (deflection) 3°

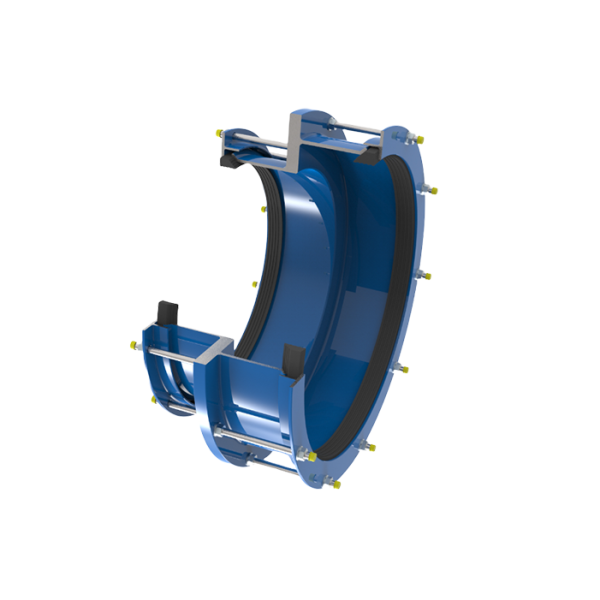

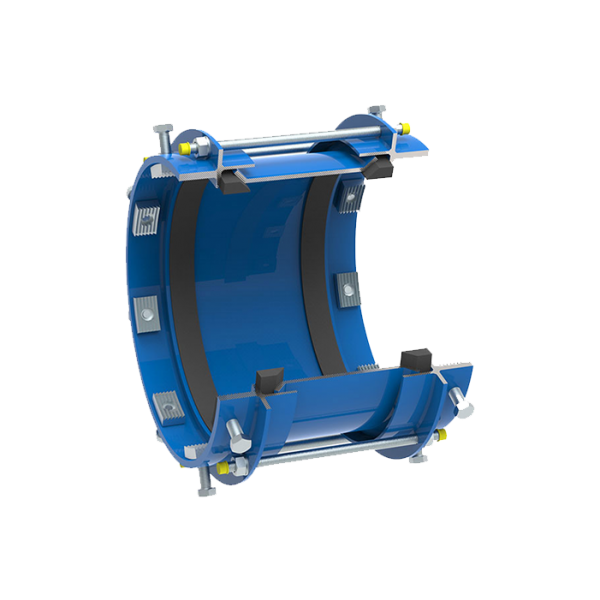

Max coupling

Features:

• Body and end ring made of ductile iron

material EN-GJS-500 (GGG 50) in

accordance with EN 1563:2018 standard

(optional body and end caps from hot

rolled structural steel)

• Couplings produced in accordance with

EN 14525:2004

• Protection with epoxy coating or black

thermoplastic coating confirmed by a

health inspection certificate

• PN16 working pressure.

• Equipped with steel zinc coated bolts,

nuts and washers

• EPDM rubber seals in accordance with EN

681- 1:1996

• High Tolerance mechanical pipe fittings.

• Angular deflection +/- 6

DOWNLOAD SPECIFICATIONS (PDF)

Flangе adaptor with restrains against pull-out

• For installation on cast iron / ductile, steel, Asbestos cement, PE

and PVC pipes

• Produced in accordance with EN 14525: 2004

• The body, closing ring and clamps made of hot rolled structural

steel ST235JR standard EN 10025-2:2019 or ductile iron in

accordance with EN 1563:2018

• Epoxy paint surface protection of min 250 μm in accordance with

EN 14901:2014 or thermoplastic in black or blue (Rilsan Nylon 11

or equivalent), confirmed by an accredited laboratory issued health

safety report

• Operating pressure PN10, PN16, PN25

• Connecting dimensions in accordance with EN 1092-

1:2007+a1:2013/AC:2014 or EN 1092-2:1997

• Galvanized steel or cast-iron pull-out clamps

• EPDM rubber seal in accordance with the EN 681-1:1996

• A3:2005 with an accredited laboratory issued health safety

certificate

• Angle deviation (deflection) 3°

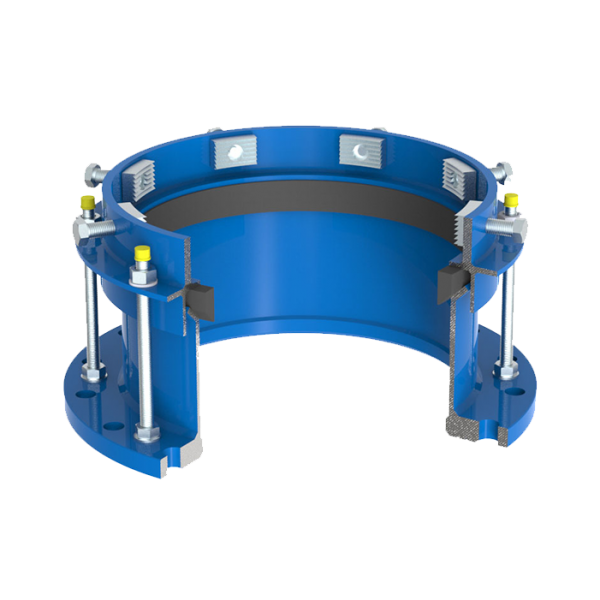

Steel Max coupling for large diameters

Features:

• Body and end ring made of hot rolled

products of structural steel St235JR in

accordance with EN 10025-2:2019 or ductile

iron in accordance with EN 1563:2018

• Couplings produced in accordance with EN

14525:2004

• Protection with epoxy coating in accordance

with EN 14901:2014 or black thermoplastic

coating confirmed by health inspection

certificate

• PN16 working pressure

• Equipped with steel zinc coated bolts, nuts

and washers

• EPDM rubber seal in accordance with EN

681- 1:1996

• High tolerance mechanical pipe fitings

DOWNLOAD SPECIFICATIONS (PDF)