Above Ground Hydrant DN80 Type ’’MT-C2’’

Features:

• Vertical installation of water or fire installation.

• Automatic discharge after use.

• Surface corrosion protection with externally and

internally applied epoxy coating with minimal

thickness of 250μm in accordance with EN 14901:2014

• Working pressure PN16.

• Connecting flange in accordance wirh EN 1092-2.

• Aluminum couplings

DOWNLOAD SPECIFICATIONS (PDF)

Above Ground Hydrant DN80 Type ’’МТ-Inx3’’

Features:

• Vertical installation of water or fire installation.

• Automatic discharge after use.

• Surface corrosion protection with externally and

internally applied epoxy coating with minimal

thickness of 250μm in accordance with EN

14901:2014, RAL 3000

• Working pressure PN16.

• Connecting flange in accordance with EN 1092-2.

• Aluminum couplings

DOWNLOAD SPECIFICATIONS (PDF)

Aboveground hydrant DN80 type МТ-INX4 – breakable

Features:

• Vertical installation of water or fire installation.

• Automatic discharge after use.

• Surface corrosion protection with externally and

internally applied epoxy coating with minimal

thickness of 250μm in accordance with EN

14901:2014, RAL 3000

• Working pressure PN16.

• Connecting flange in accordance with EN 1092-2.

• Aluminum couplings

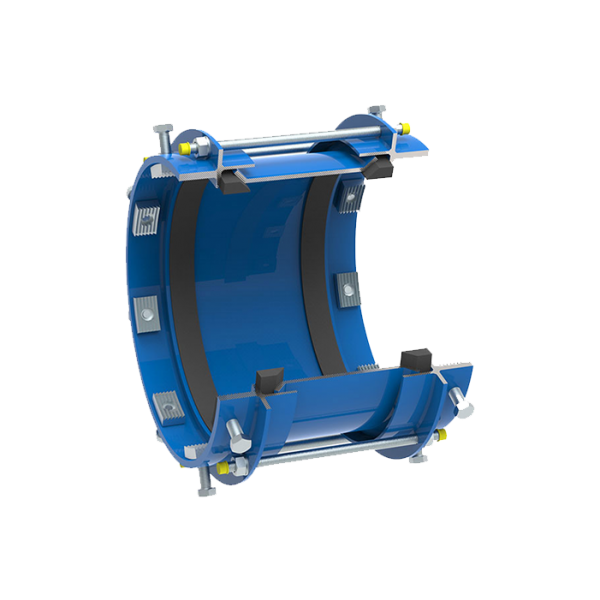

Coupling with restrains against pull-out

Code No. АТА 07264

Features

- For installation on cast iron / ductile, steel, Asbestos-cement, PE and PVC pipes

- Produced in accordance with EN 14525: 2004

- The body, closing ring and clamps made of hot rolled structural steel in accordance with EN 10025- 2:2019 or ductile iron in accordance with EN 1563:2018

- Epoxy paint surface protection of min 250 μm in accordance with EN 14901:2014 or black thermoplastic confirmed by an accredited laboratory issued health safety report

- Operating pressure PN10, PN16, PN25

- Galvanized steel or cast-iron pull-out clamps

- EPDM rubber seal in accordance with the EN 681-1:1996 with an accredited laboratory issued health safety certificate

- Angle deviation (deflection) 3°

Decorative water drinking fountain Type Antonia

Features:

• Baroque style shaped

• Self closing push button – high gloss brass faucet or classic tap with

½” connection to a flexible water pipe

• Epoxy coated 250µm, RAL 9005; 6002; 6010 – UV stabilized

• Grey iron casting GG20, standard EN 1561:2011, casting thickness

min 8mm

• Field of application - water drinking fountain for public use in parks,

gardens, town squares

DOWNLOAD SPECIFICATIONS (PDF)

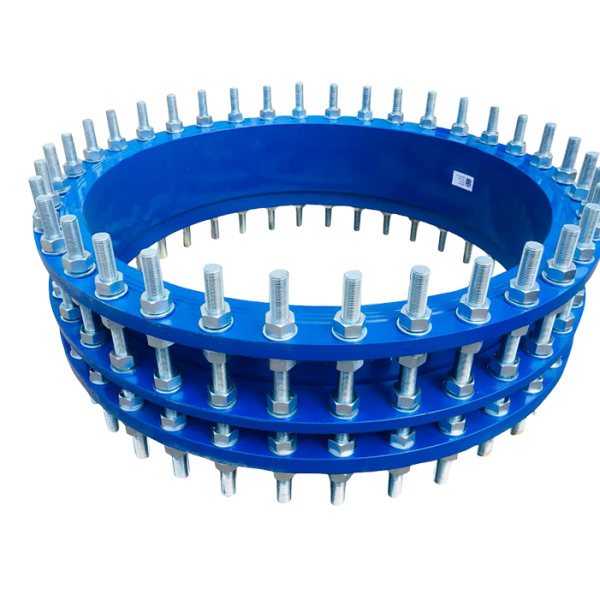

Dismantling joint type MDK A

• Dimension Range: DN50 to DN2000.

• Working Pressure: PN10, PN16, PN25, PN40

• Pressure test in accordance with EN 12266-1:2012

• Flange Drilling: EN 1092-2:1997 оr EN 1092-

1:2007+A1:2013

• Epoxy paint surface protection of min 250 μm in accordance

with min 250μm according EN 14901:2014 or thermoplastic

confirmed By an accredited laboratory issued health

inspection certificate

• Sealing ring made by EPDM in accordance with EN 681-

1:1996/A3:2005

Ductile iron double band repair clamp

Features:

• Body produced from ductile iron in accordance with EN1563:2018

• Epoxy coating protection of min. 250μm in accordance with

EN14901:2014 or black thermoplastic confirmed by health

inspection certificate

• PN16 working pressure

• Equipped with steel zinc coated bolts, nuts and washers

• EPDM rubber seal in accordance with EN 681-1:1996

• Ductile Repair Clamps are intended for permanent repair of pipes

from various materials

DOWNLOAD SPECIFICATIONS (PDF)

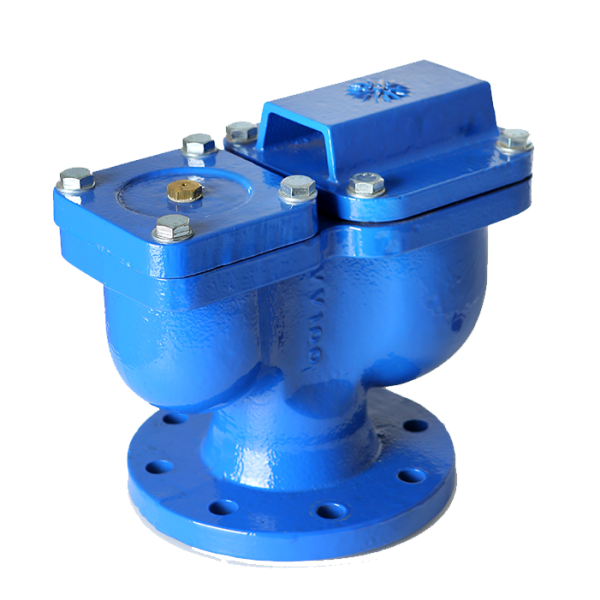

DVV – Automatic air valve with twoo balls

Features

• Design: EN 1074-4:2000

• Available range of DN sizes DN 50

to DN 200.

• Epoxy coated from the inside and

outside, min 250 μm in accordance

with EN 14901:2014

• Product color: Blue RAL 5005.

• Working pressure PN10 and PN16.

• Discharge of large amounts of air

when filling a pipeline

• Discharge of small amounts of air

during the operation of the pressure

pipeline

• Entrance of large amounts of air

when emptying a pipeline

DOWNLOAD SPECIFICATIONS (PDF)

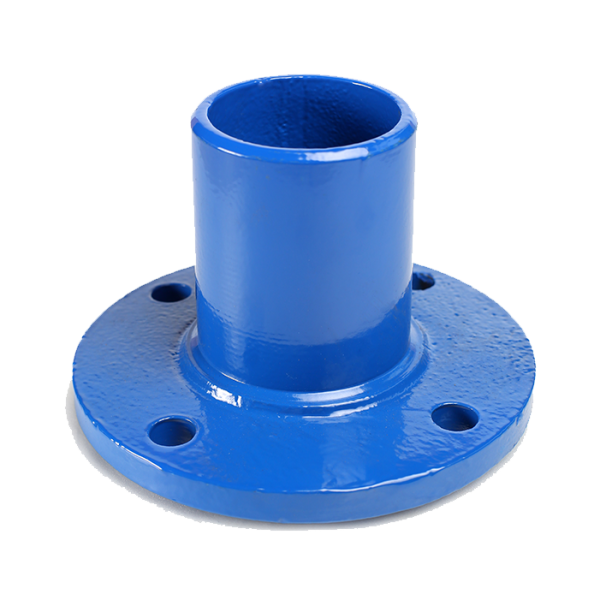

F – Flanged pipe

All cast iron pipe pieces are made in accordance with EN 545, which specifies the material, mechanical features, measurements, permitted tolerance and protection of all parts.

These ductile iron products are intended for a working pressure of 10 bar

and 16 bar. The protective layer of these ductile iron pipe fittings is made

with a health friendly material.

These fittings attach to the flanges with the help of screws.

Epoxy paint surface protection of min 250μm in accordance with EN

14901:2014 or thermoplastic confirmed by an accredited laboratory issued health inspection certificate

DOWNLOAD SPECIFICATIONS (PDF)